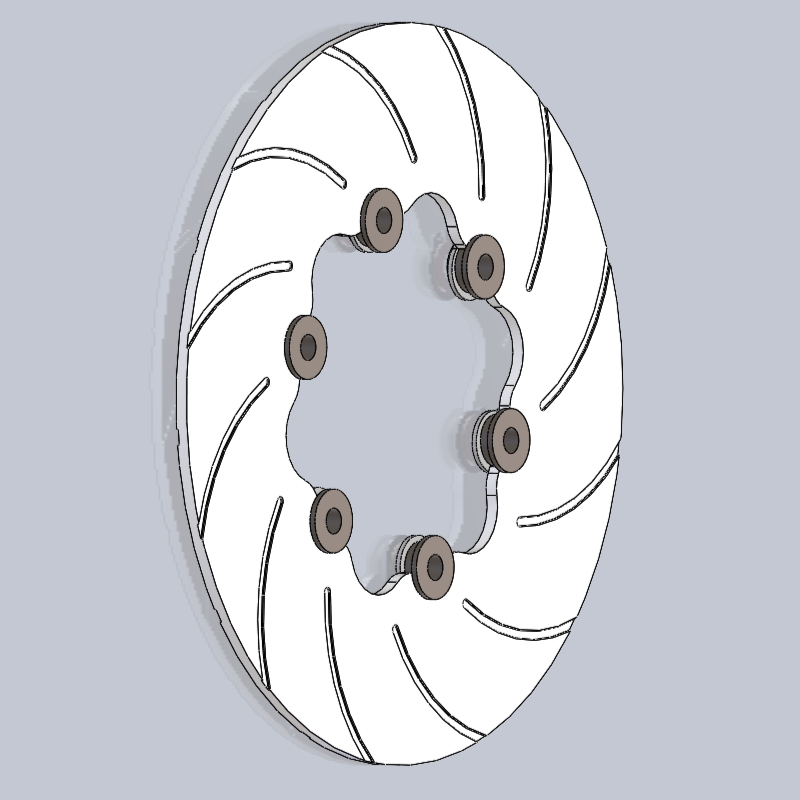

Front Brake Rotor 2022-23 (3D)

Brakes (Over the years)

FSAE EV 2022-2025 Braking Systems

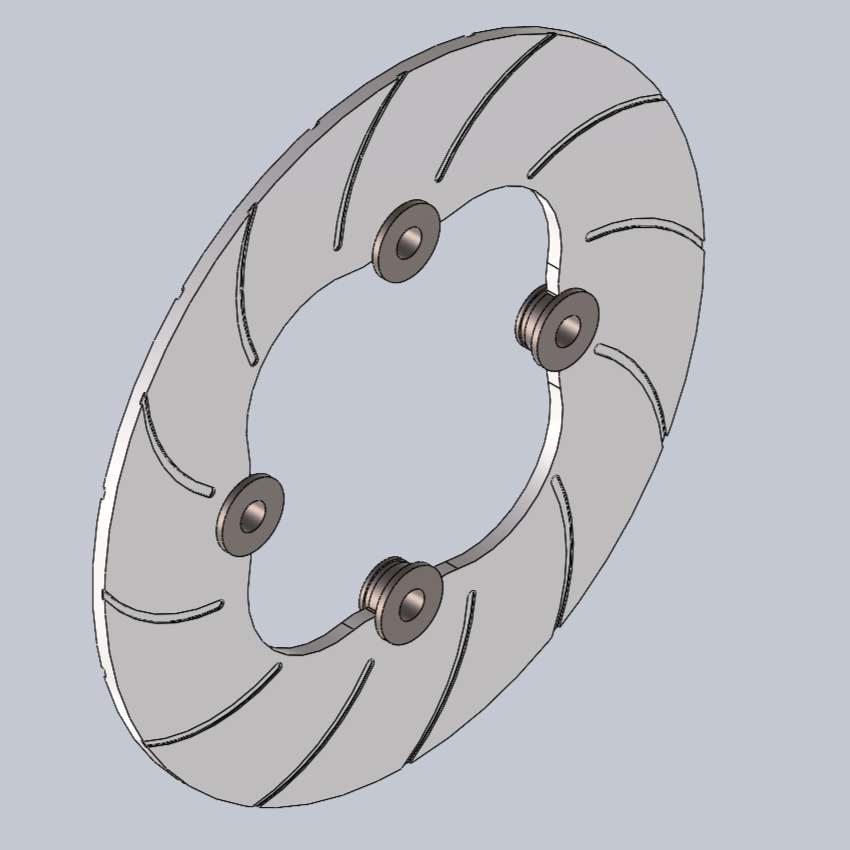

Front Brake Rotor 2023-24 (3D)

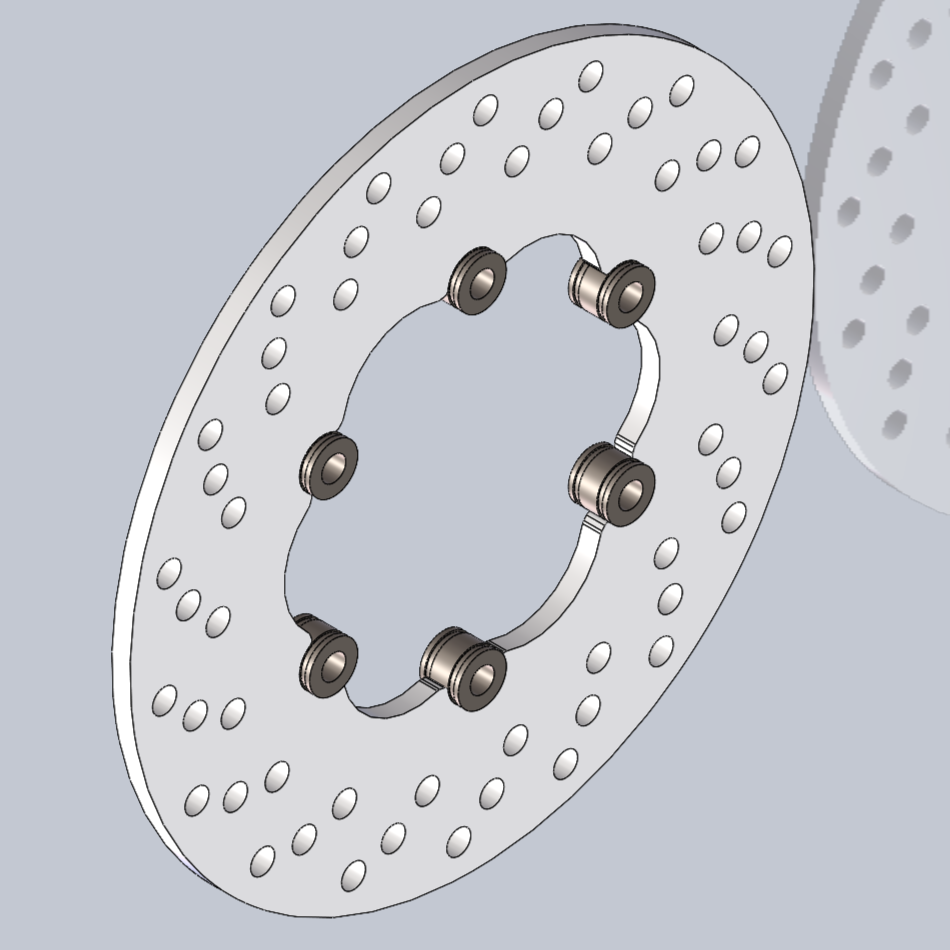

Front Brake Rotor 2024-25 (3D)

Rear Brake Rotor 2022-23 (3D)

Rear Brake Rotor 2023-24 (3D)

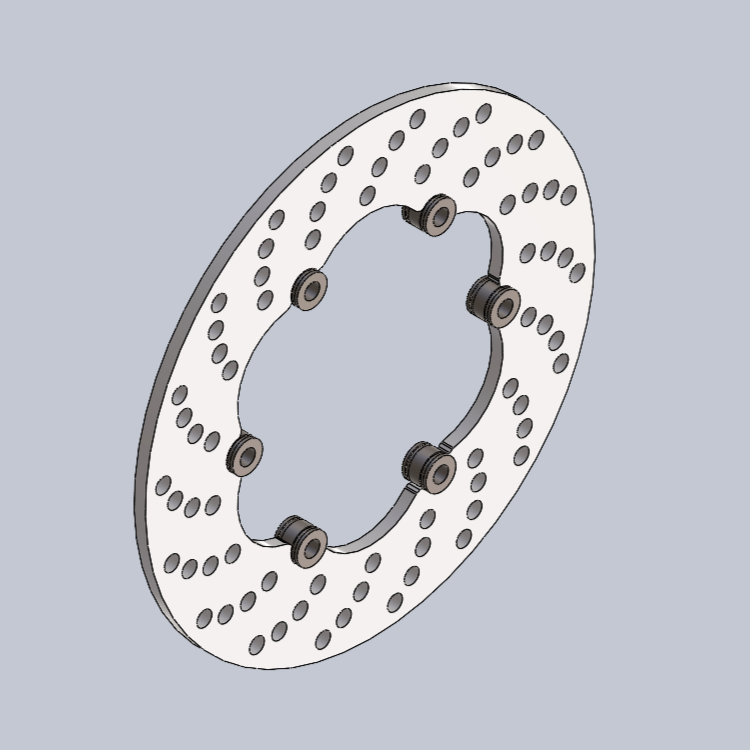

Rear Brake Rotor 2024-25 (3D)

Pedal Box 2024-25 (3D, I only partially owned this part)

Rules and Requirements

Although the rules for braking systems have varied mildly over the years, the major requirements that

drive the design have been static and are paraphrased as follows from the 2026 FSAE Rules:

-

T.3.1.2: Brake system must act on all four wheels from a single control and be capable of

locking all four wheels

-

T.3.1.3: There must be two independent hydraulic circuits, each with their own fluid reservoirs

-

T.3.2.1: The brake pedal must be made from steel, aluminum or titanium

-

T.3.2.2: The brake pedal must withstand 2000N (or a judge's strongest stomp)

at the pedal face without any failures in the system

-

T.3.1.2: Brake system must act on all four wheels from a single control and be capable of

locking all four wheels

-

T.3.2.4: The first 90% of a brake pedal may be used to regenerate energy without actuating the

hydraulic braking system

-

T.4.3.1: The vehicle must have a Brake Pedal Position Sensor or a Brake System Pressure sensors

2024-25 (Brakes Lead)

For the 2024-25 season, the Brakes system was split off from the unsprung sub-system again as it proved to be an excessive amount of work for one subteam to handle. As I had the most experience with Brakes, I was chosen to lead this subsystem. This was the first year that the brakes subsystem had more than 2 people on it, therefore we made it a mission this year to question EVERY choice and justify all design choices from first principles or from a practicality standpoint. Notable changes during this year include the rotors losing their holes, as these were removed in favor of small, dust-clearing divots. This ensured that the surface area of the rotor was maximized for both braking torque and cooling purposes. Another notable change in the assembly was the switch to Titanium grade-5 brake buttons. This was driven by circumstance as the UT Austin Machine shop had limited student access, so more parts needed to be outsourced, and Titanium brake buttons were very similar in price to 4140 but offered major advantages in weight, strength, and thermal resistance (4.45$\frac{g}{cm^3}$, 6.7$\frac{W}{m^\circ K}$ vs. 7.85$\frac{g}{cm^3}$, 42.6$\frac{W}{m^\circ K}$).

2024-25 Front Brake Rotor Assembly

2024-25 Rear Brake Rotor Assembly

After a design judge told us our most FSAE brake rotors were "an aesthetic expression" instead of designed

around functionality, we went back to the drawing board and came up with a new front brake rotor that

was capable of achieving locking torque and while keeping temperatures minimal.

There was also a lot more testing put into the thermals of this part, such as checking rotor temps after

an autocross event, applying thermal paint to the rotors (failed), and installing rotor monitoring thermal

cameras (16x16 px, 1 Hz sampling was too slow to provide any real value).

Once again, due to packaging issues, we had to modify our rear brakes down to one rotor. Calculations indicated that one rotor with a P2.24 caliper would easily provide the torque necessary to lock the rear wheels if we were willing to run higher line pressures (within the burst rating of the master cylinders and calipers), but braking through the diff would cause constant understeer. Another complication that arose for rear braking was the reintroduction of regenerative braking from the motor, this meant that the hydraulic braking torque had to be varied based on battery SOC and motor RPM. I will discuss this more below.

2023-24 (Unsprung Member)

During my second year, the brakes system was absorbed by the hierarchically larger "Unsprung" system and the rear brakes once again shifted inboard as packaging issues were resolved. During this year I was also involved in the design of the Front Wheel Hub as it made integration much easier to have one person own the design of two components that fit together. I was able to continue positive relations with COTS suppliers from the previous years to receive another free set of P2.34 to use as front calipers, and in addition I was able to acquire a set of P2.24 calipers for the rear of the vehicle. A notable design change during this year was the switch to 4140 Hot-Rolled Steel Rotors and slotting the rotors instead of drilling them for pocketing and dust clearing. This design change was made as we (me) had fractures in rotor blanks during manufacturing the previous year, and we hoped switching to a more ductile material would reduce some of these failures (0.5% elongation vs. 10% elongation). A large amount of this year's design changes were aimed at easier manufacturing from experiences the previous year, this included features such as dowel pin holes/slots (to rotationally locate the rotors in our mini mills).

2023-24 Front Brake Rotor Assembly

2023-24 Rear Brake Rotor Assembly

The geometry of the front brake rotor followed a similar design philosophy to the previous year, with very minor changes being made to the exterior as that region did not contact the brake pad. The slotting on this rotor was a little less arbitrary in that it only existed where the brake pad contacted and had chamfers. This was aimed at clearing any dust/debris that accumulated on the brake pads, and the angle in the slots was to ensure that braking force (dictated by pad contact area) remained constant irrespective of rotation.

Similar to the previous year, the rear brake rotor geometry was mostly a modification of the front brake rotor. However, unlike the previous year, inboard brakes posed a much nicer packaging constraint, allowing us to utilize a larger caliper and a smaller rotor. Although inboard brakes introduced compliance into the system via the torsion of the driveshaft, it was deemed necessary as the tripod increased in size over the previous year; this made it impossible to package brake rotors and calipers in the rear unsprung assembly without major assembly and clearance issues.

2022-23 (First Year Student)

As a freshman at UT Austin, I was assigned the design of brake rotors and relevant COTS Selection as my responsibilities. This included sourcing brake calipers (which I procured for free) and sourcing master cylinders compatible with the pedal box. This year was a rebuild year for the team at large as the dynamics team grew from 4 people to 18 (of which all new members were freshman). This also meant that there was next to zero knowledge transfer from upperclassmen, forcing me to derive all designs from scratch with very little reference material. As a result, to produce a viable rotor in a reasonable amount of time, we opted to continue with Gray Cast Iron as our material choice.

2022-23 Front Brake Rotor Assembly

2022-23 Rear Brake Rotor Assembly