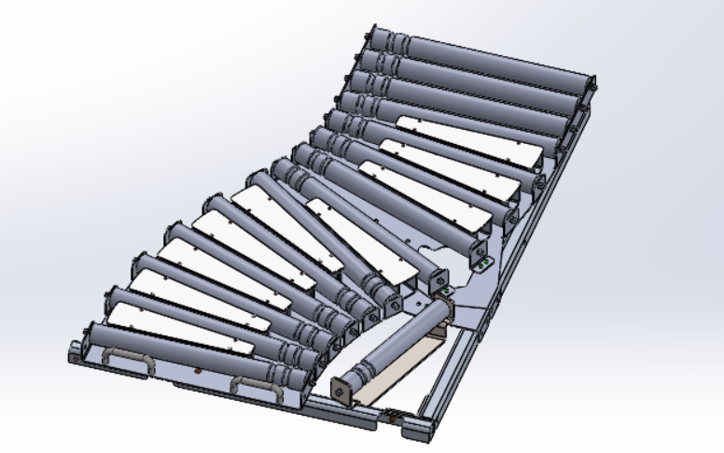

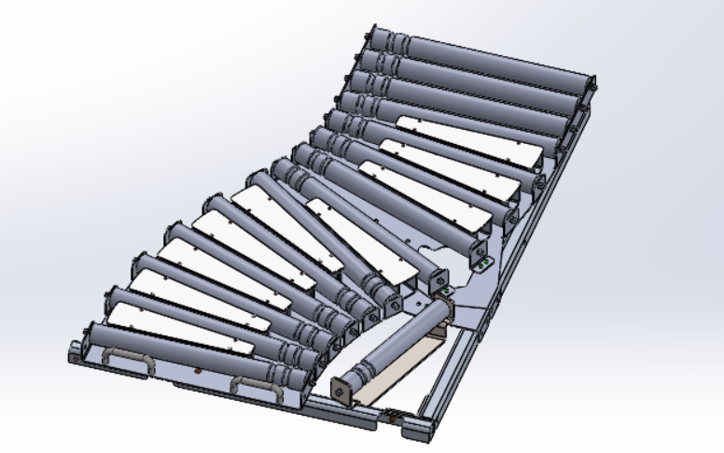

Conveyor Iteration Two (no unloading failures during lifespan)

Chassis-Mounted Conveyor to improve unloading reliability

Conveyor Iteration Two (no unloading failures during lifespan)

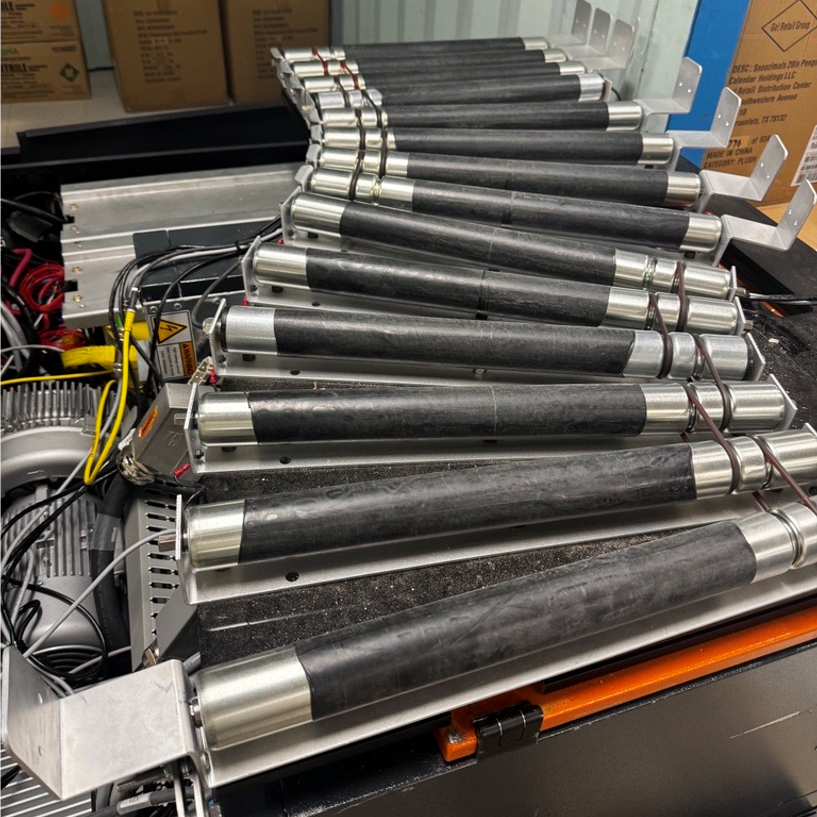

First Conveyor with an Acrylic Base-Plate