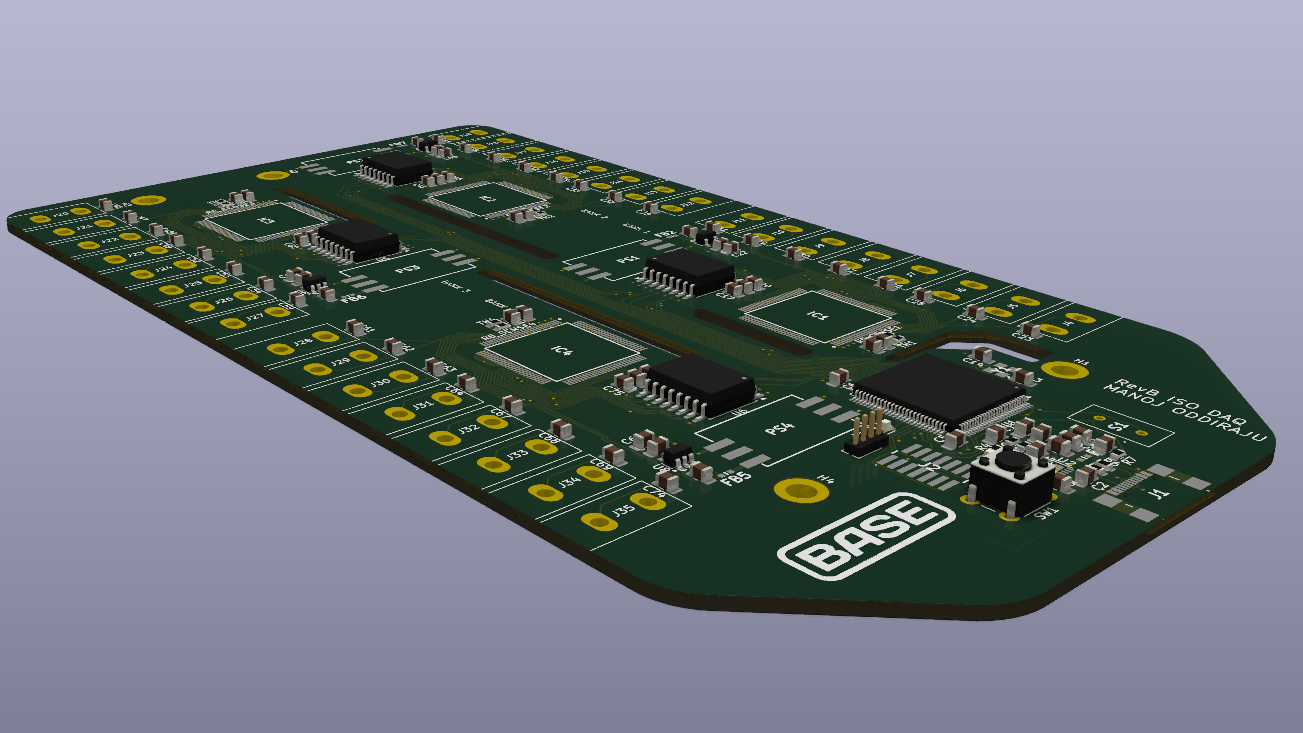

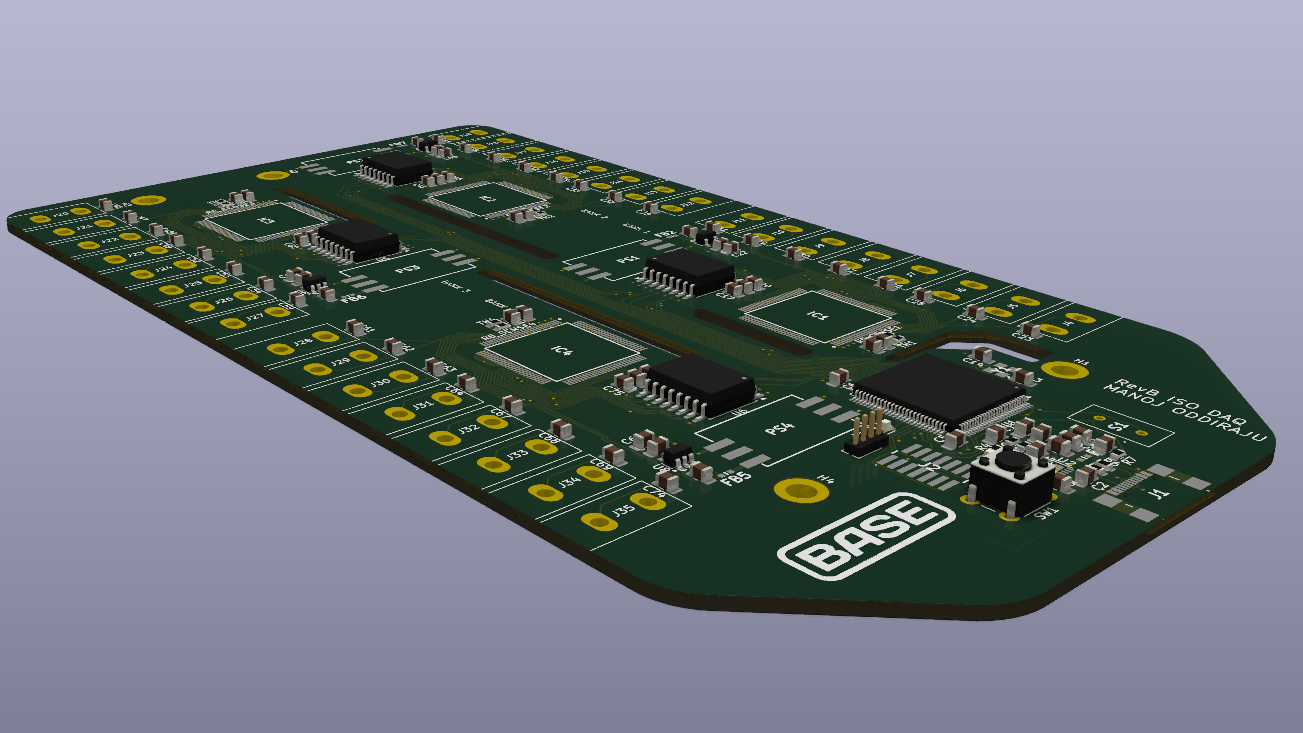

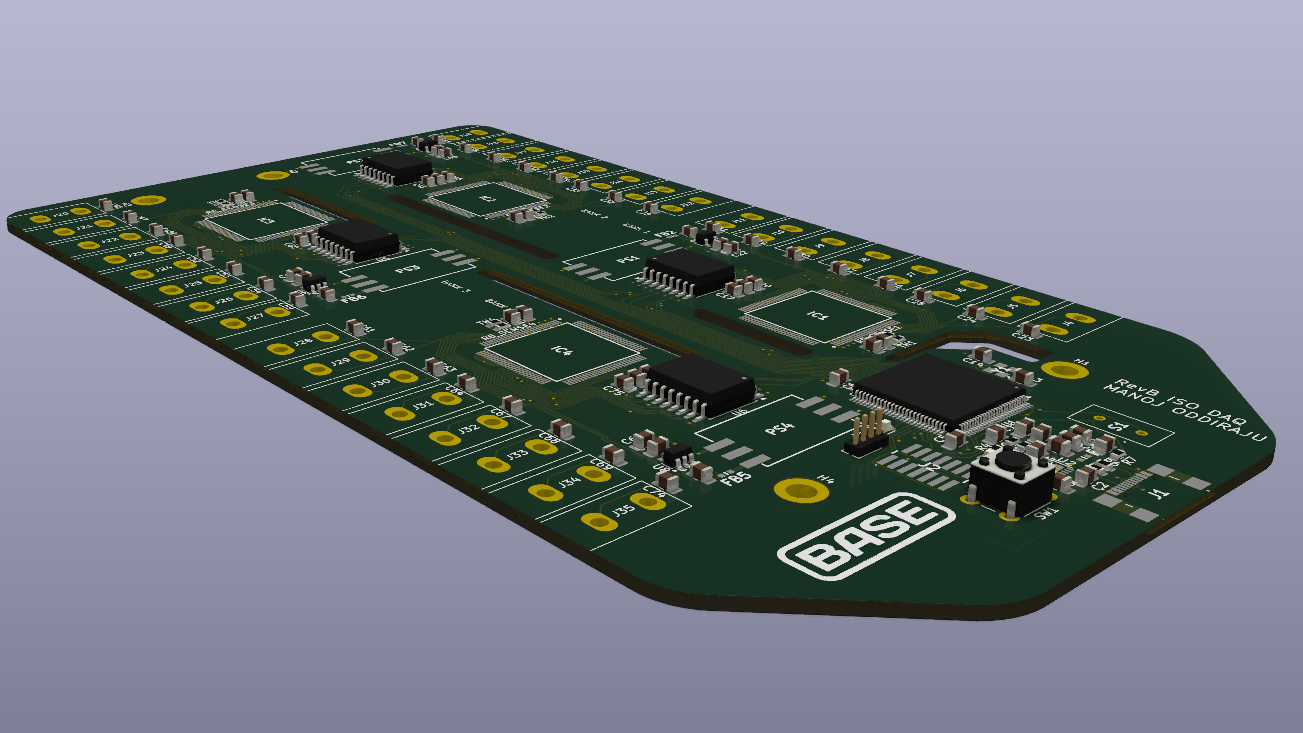

KiCAD Render

This project was handed to me to continue outside of Base Power (and eventually share the final product with them).

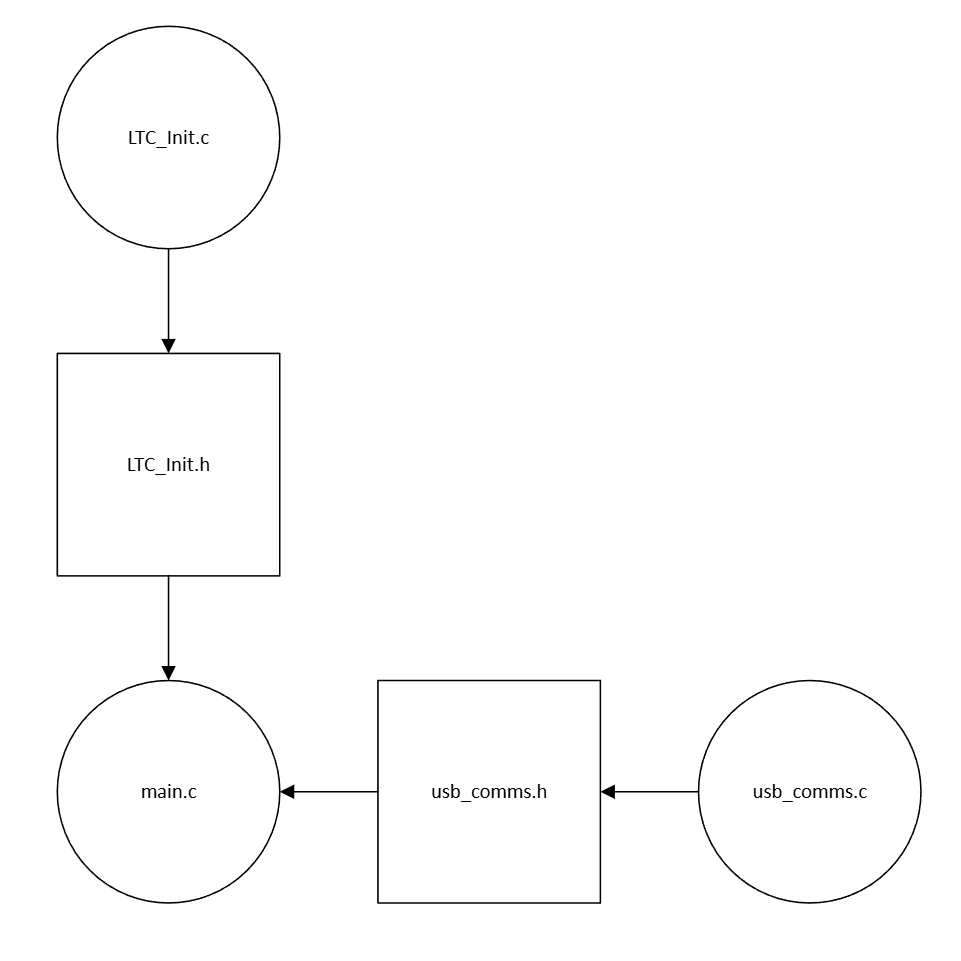

I am developing firmware, which I intend on testing once I get a board in hand. I'll be very happy to discuss details

about this project in any interview!

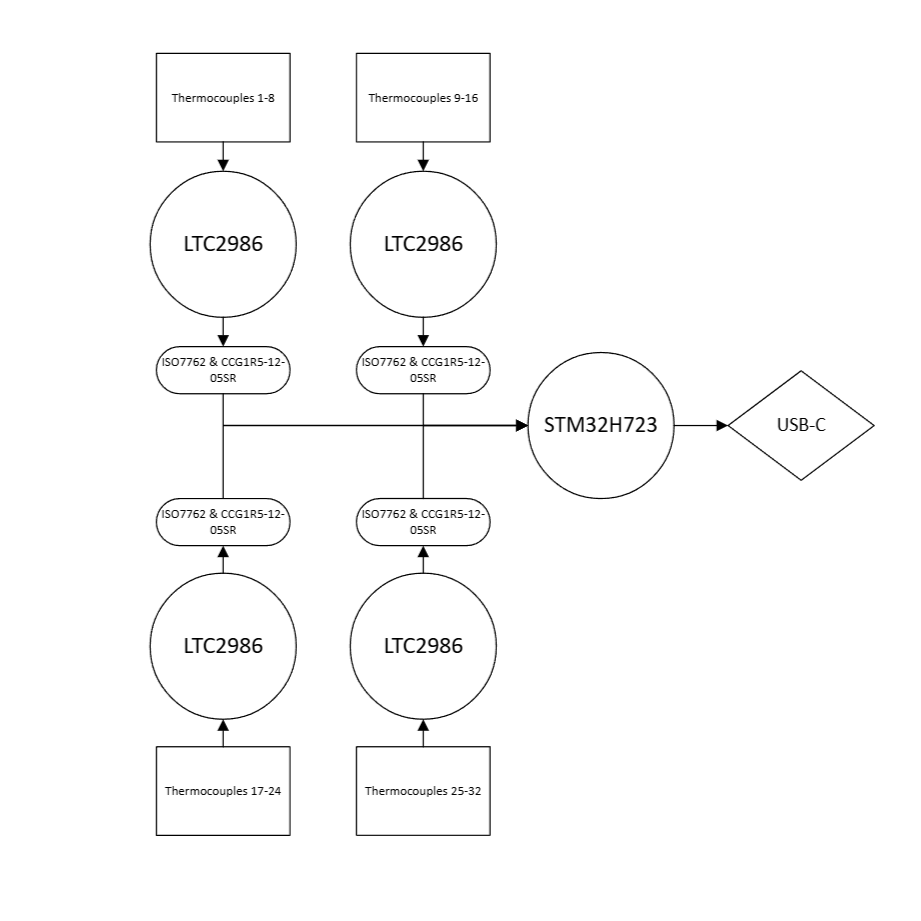

The intent of this project is to develop a DAQ capable of reading 32 thermocouples simultaneously while isolating the thermocouples

into groups to protect against unintentional high-voltage contact.

This project is estimated to cost between $150-200 per board (to be updated once I get a JLCPCB quote, this

estimate is from a BOM cost estimation + ~$50 for soldering), while

the cheapest thermocouple DAQ

I could find

is approximately ~$475, and that too for an 8-channel logger with a 24 hour logging rate at 1 sample per second at most.